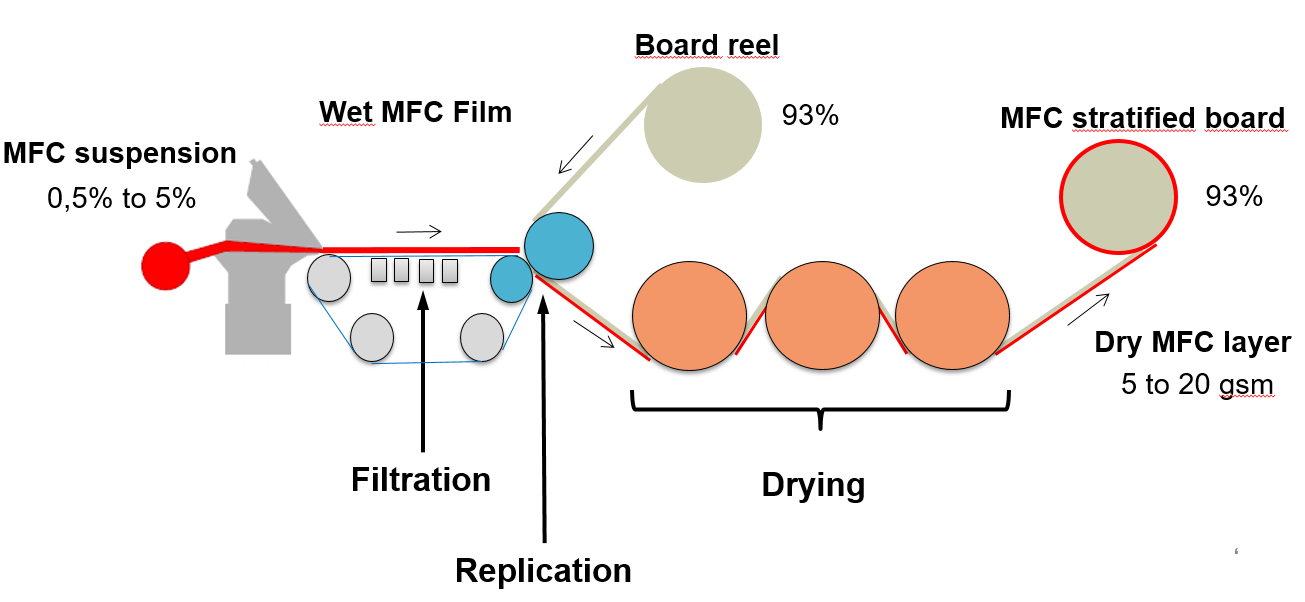

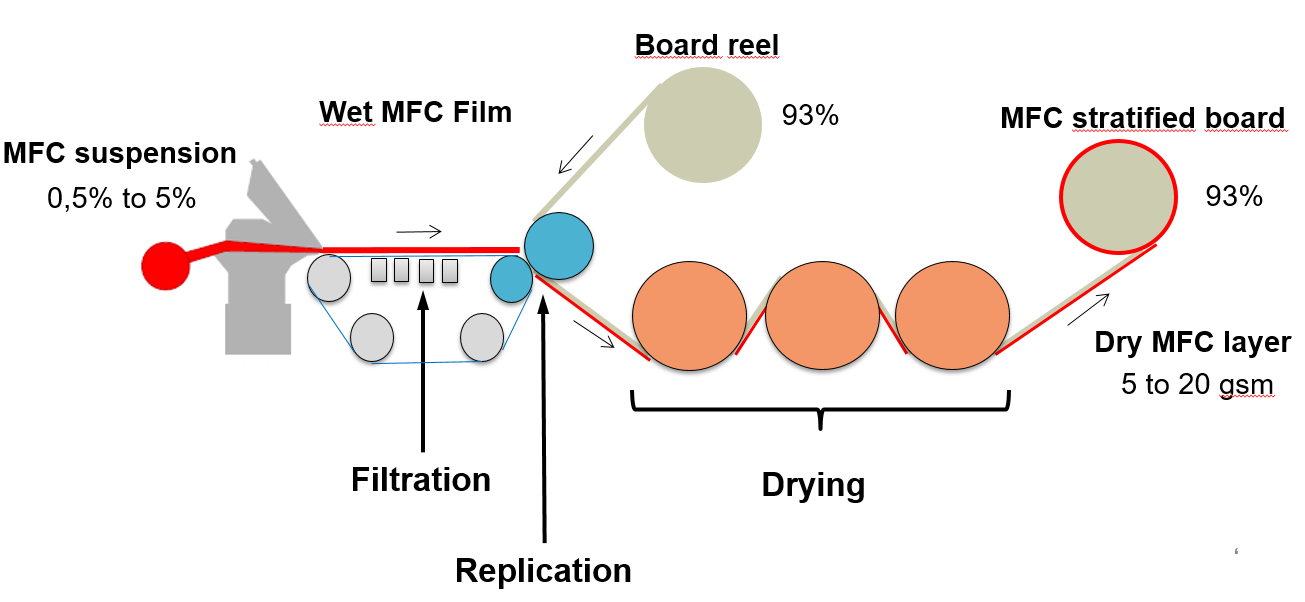

Drawing 1 illustrates the concept of the wet lamination method described.

Wet lamination process.

Cold foil printing also known as cold foil stamping is a modern method of printing metallic foil on a substrate in order to enhance the aesthetic of the final product cold foil printing can be done two ways.

Lamination is the technique process of manufacturing a material in multiple layers so that the composite material achieves improved strength stability sound insulation appearance or other properties from the use of the differing materials such as plastic a laminate is a permanently assembled object created using heat pressure welding or gluing.

Another lamination process uses a lamination press after materials are combined in a thicker structure than film.

Impossible to trap air bubbles.

Wet bond lamination is a laminating process used to laminate two substrates one of which is porous such as paper.

No drying is required.

When only the two layers are involved the process is known as extrusion coating.

Laminating machinery can be classified according to the type of bonding agent used to produce the laminates.

The older dry lamination process common in the offset printing industry or the newer more versatile wet lamination process which is dominant in the flexo label industry.

The laminate then passes through the chilled nip of the combiner roll cooling the plastic layer which solidifies.

However the material properties in the wet lamination process are not as good as with other processes.

Where the bonding agent is still in a liquid state when the webs are joined together.

It is commonly used to produce a paper aluminum foil laminate that is widely used in flexible packaging.

Laminating is the process through which two or more flexible packaging webs are joined together using a bonding agent.

Particles and other surface contaminants are washed away by water.

Water is the source of heat and therefore eliminates the need for a hot roll laminating machine.

Wet lamination showed to have the following advantages.

Once the wet bonding process is applied to each substrate the two substrates will then be combined prior to passing through an.

The wet lamination process can be used for the cost effective manufacture of components in simple shapes.

The large proportion of manual production requires well trained specialists and careful quality control.

As an example azdel a glass reinforced thermoplastic composite made with continuous glass mat is produced using an extrusion lamination operation film continuous random orientation glass mat and molten resin are combined in a lamination process using a sandvik double belted.

The hot melt process is used for high speed lamination since there is no need for a drying stage.